Нow to sharpen scissors professionally

Scissors, being an everyday household tool, have been known for quite a long time, but who and when invented and used them first is unknown. The fact remains that this item has undergone many design and technological changes and has turned into a very high-tech product. Some scissors are easier to produce and maintain, and some require special skills, experience and equipment.

Depending on the purpose the scissors are divided into several basic types:

- Hairdressing

- Nail

- Kitchen

- Office

- Crafting

- Garden scissors

- Metalworking

- Medical

Within one type of scissors there are completely different manufacturers and a large number of sizes and models. As an example, there is a variety of shapes and combinations of cutting edges of hairdressing scissors, which are one of the most difficult types of scissors to maintain and sharpen.

1. The design features of the scissor types

Hairdressing scissors are grouped into three subgroups and differ in the design of the cutting edge:

- Straight

- Thinning

- Chunking

Straight scissors most often have a range of standard sharpening angles from 40-50 degrees, depending on the manufacturer. For precise cutting there are types of grinds with sharper angles of about 38 degrees, which can be found on professional tools made in Japan. In addition, straight scissors may have various shapes of the working surface of the blades, stretched in a line or curved.

The thinning scissors have one characteristic feature, which is the arrangement of the teeth on one or both blades. The thinning teeth can have different sharpening angles, which are chosen according to the characteristics of the steel used for manufacturing.

Chunking scissors represent a combination of classic and thinning scissors. One of the blades of such a tool can be equipped with teeth, and the other uses a removable attachment of a certain shape.

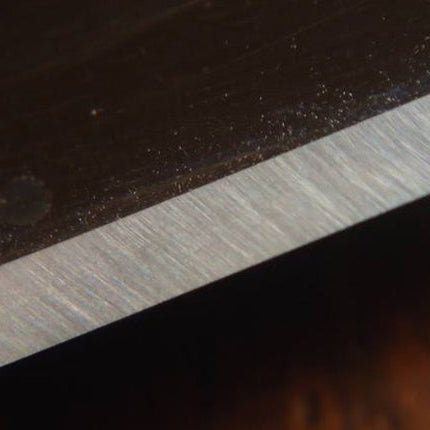

It should also be noted that among all hairdressing scissors there are two types of the cutting edge. There are scissors with convex and regular secondary bevels and semi-convex and regular secondary bevels.

The standard grind type is the sharpening of the straight blade secondary bevels at an angle ranging from 40 to 50 degrees, depending on customer requirements or pre-shaped factory grind.

Semi-convex grind is a type of step sharpening - a transitional type from standard to convex grind. The step sharpening can be shaped in three planes with angles ranging from 10 to 25, 30 to 40 and 42 to 45 degrees.

Convex grind can have even smoother transitions of angles and have up to four planes, for example: 10-20, 25-30, 30-35 and 38-42 degrees. These transitions are often invisible to the naked eye, due to the polished surface. However, if you consider the Japanese scissors, you will immediately notice that there is a smooth convex grind. From a technical point of view, one blade has a stepless convex grind. We can also say that the cutting edge is formed by a straight and curved planes.

How the type of grind on hairdressing scissors affects the work

The type of grind directly affects the cutting technique that the hairdresser will use. The Scissors with standard secondary bevels are suitable for straight cuts and fading, but slicing cuts will not be possible because the cutting edge will catch and tear the hair due to the small sharpening angle.

With semi-convex scissors, it is possible to perform straight and slicing cuts at a fairly satisfactory level.

On the contrary, the scissors with convex are great for straight cuts as well as for slicing. They are the sharpest, smoothest in tactile response, and also the most expensive. Here you just need to exclude cheap copies of branded products, from which you should not expect the same result as from the originals.

Since the grind and blade types are sometimes combined, it is the scissors for thinning that represent the highest level of difficulty in sharpening and require a highly skilled sharpener.

There is one more detail in sharpening hairdressing scissors and scissors in general - it is notching, which improves the quality of the cut. How one or the other type of grinds is made will be described below in the section No. 2.

Overall recommendation:

- The scissors with a support plane allow the most precise cutting.

Nail scissors are designed for manicure procedures, they have a compact size, a special shape and characteristic small cutting blades with narrowing to the tips. The scissors for nails are divided into 4 types:

- For nails

- For cuticles

- Universal

- Safe

Nail scissors can have a medium length, a flat or often curved blade for the most comfortable and precise cut.

The cuticle scissors have a slim, sleek design with curved blades and special grind. These scissors are not recommended for cutting nails because of the nature of the blades and the grind.

Universal scissors sometimes have a peculiar blade profile - wide at the base and then sharply turning narrow with sharp tips. These scissors can perform quite well in nail and cuticles cutting.

The safety scissors have a rounded tip not typical of most nail scissors and are used for trimming children's nails. These scissors are mostly made with straight blades and regular grind.

General recommendation: for proper sharpening, the back surface (concave side) is grinded, then the general shape is given, then the lower blade grind line is sharpened, then the upper blade grind line, and after the bevels. Sharpening angle of nail scissors can be around 70 degrees, depending on the manufacturer.

Kitchen scissors are used for many different tasks in the kitchen and in most cases have a straight blade. Quite often you can find a special notch on such scissors, which increases the efficiency of cutting packages, fins or slicing herbs.

General recommendation: for the kitchen and household scissors, a 60 degree angle is considered sufficient.

Office scissors are mostly straight with a simple grind from 50 to 70 degrees. They vary in length and width of the blades. Larger ones are used for cutting cardboard, and shorter ones for cutting paper. Often used for needlework at home and by children at school.

General recommendation: the 60° angle for the straight blades of office scissors is almost perfect.

Crafting scissors have straight, sharp blades of universal length and a recognizable shaped handle. The bottom ring is much larger than the top ring and provides room for four fingers, which helps when working with heavy materials.

This type of scissors can be used both for light and dense materials. The peculiarity of this type is that the lower blade slides under the fabric, and there is no need to work while holding the material in the air. These scissors also have a simple type of the grind, but it is necessary to pay attention to what materials the scissors are used for, in order to make the secondary bevels sufficiently sharp.

General recommendation:

- micro serrations on the edge of the upper blade can provide a more efficient cutting quality

- do not perform fine finishing, the key is to make a clean, sharp and sufficiently aggressive cut

Garden scissors can have different sizes, designs and shapes of the blades depending on their purpose. These shears quite often resemble much larger and more massive garden pruning shears, but still have differences. Among these scissors there are subgroups but mainly they are characterized by their shape designed to cut plants and branches.

The working blade and the blade for support of the scissors have different grinds. The first provides a direct cut, and the blade for support holds the grass or branch so that it does not move away.

The edge of the working blade is very sharp. It has a smooth bevel, so it bites into wood or grass stems with minimal resistance. The blade for support is short and its edge is less sharp. If the scissors are designed to work with wood, the edge of the blades have a concave inward shape. This provides a secure hold on the branches.

General recommendation: most garden scissors and pruning shears have only edge of the working blade sharpened. The blade for support can be honed on a machine with a special disk, with a sharpener you can use a special semi-circular bar or you can hone the blade manually with a file or a honing rod.

Metal working manual scissors are designed for straight or curved cutting of sheet metal, roofing material, metal roofing tiles, tin sheets, etc. This type of scissors can be all-milled and collapsible.

The sharpening angle of the edge of the blades is 60-75 degrees. This sharpening angle provides high performance with minimal effort. The large sharpening angle means that the tool can be used for cutting hard metal sheets.

The cutting elements are made of alloy or tool steel and this must be taken into account during sharpening.

General recommendation: sharpening of metal scissors depends on the thickness of the materials to be cut - the thicker the material, the greater the angle, it is desirable not to sharpen the back, i.e. the inner surface.

Medical scissors

We can talk about medical scissors within the kinds that do not require regular disinfection and are used outside the medical facilities, specifically scissors for cutting bandages. They can be made of hard alloys and have a straight blade on one end with a button to penetrate deep into the bandage.

General recommendation: the blades of the medical scissors can be curved and quite rigid, so you can not choose large sharpening angles.

2. The range of sharpening systems

Today, sharpening workshops and sharpeners have at their disposal a certain range of devices, which allows to sharpen scissors and divides the sharpening itself into domestic and commercial. The reason for this is the approach and technological capabilities of the devices themselves.

Certainly, this does not mean that an individual cannot purchase this or that machine for himself, but that is not what we are talking about.

Of all the possible ways to sharpen scissors, the following devices and professional tools can be distinguished:

- Sharpening machines with two disks, a guide and a manipulator

- Machines with a horizontal disk combined with a manipulator

- Household sharpeners of the Apex type

- Sharpening stones

Sharpening machines with two disks, a guide and a manipulator can be rightfully considered a typical device in the list of sharpening equipment by the list of technical possibilities and the speed of work. The advantages of such a tank include:

- Possibility to sharpen various manicure and pedicure tools, almost all types of scissors with high precision of up to 5-7 units per hour

- Does not require much space

- A guide and manipulator allow fine-tuning and a high level of repeatability

- When needed, consumables can be changed on the machine quickly enough.

- The height and angle of the sharpener can be adjusted

The biggest advantage is the high productivity of such systems, which is also a disadvantage in terms of cost. These machines are used mainly in commercial sharpening and for the purpose of providing high volume and high precision.

Since the range of consumables is sufficiently wide, the craftsman makes his own decision depending on the condition of the tool that is being sharpened. Then they will have to place the scissors in the manipulator and then performs certain sharpening steps. The presence of the guide and the manipulator guarantee a high degree of precision in the machining of the surfaces that form the cutting edge. With sufficient experience with the machine and an understanding of the use of scissors or any other cutting tool, a quality result is guaranteed.

It is also possible to sharpen scissors with simple secondary bevels on the sharpening machines with simpler means of maintaining and controlling the angle, but this will not be as effective as such machines have a limited functionality.

Sharpening machines with a horizontal disk combined with a manipulator are the best equipment for sharpening hairdressing professional tools in terms of the list of components and technical capabilities. Almost any scissors can be sharpened in several steps with the horizontal disk much faster than with any other equipment. Such a machine will take up much less space than a sharpener with two disks and is much more efficient than a household sharpener, but will still be quite expensive equipment.

The sharpening consists of choosing several abrasives, installing each of the scissor blades in turn in the manipulator and processing the surfaces that shape the cutting edge to its final formation. The peculiarity or advantage of the horizontal disk is the possibility to process the radial surfaces of the blades with a conex geometry with a high efficiency due to the large contact spot of the blade along its full length with the abrasive. Afterwards, the assembly and adjustment of the coupling is done. Besides, the sharpener should have sufficient qualification to use such a machine, in order to achieve the maximum desired result.

Sometimes several machines are required, as in the case of thinning scissors, when the concave surface needs to be grinded and/or the teeth need to be notched. Thus, it is clear that even a single machine, expensive enough, is not able to do all the technical steps.

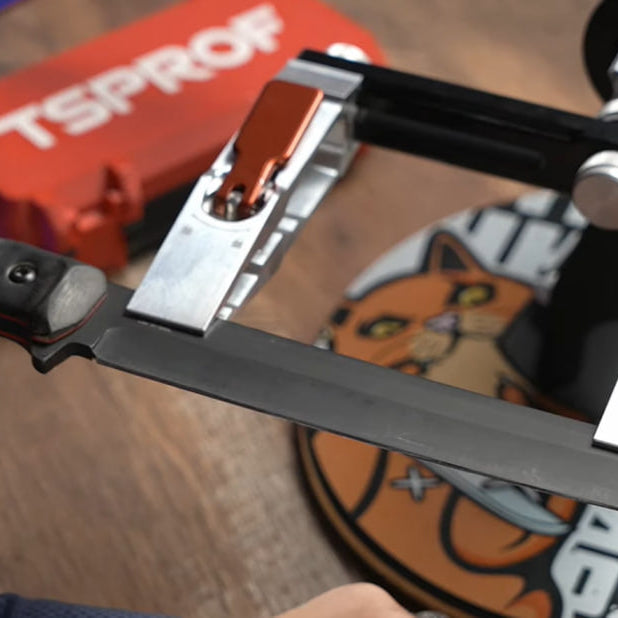

Household Apex type sharpeners are mainly used to sharpen knives, but perform almost all the same functions of sharpening a variety of scissors, with high precision, but the work rate will be much lower in comparison with power tools, but this does not make the result less qualitative. It is just that painstaking manual work can cost more than stream work.

Sharpening with such sharpeners, as in the previous cases, comes down to the choice of abrasives, disassembly of scissors, and the use of a special clamping part in combination with the sharpener. Some sharpeners come with special attachments that make it possible to fix the clamps at the required angle for sharpening scissors.

Then the sharpening angle is determined and each of the scissor blades is sharpened step by step with different abrasives, depending on their type and design.

In the case of using a household sharpener, it should be noted that only simple secondary bevels, both on straight and curved blades, can be sharpened. Scissor models with semi-convex or convex, and especially with the support surface are not possible to sharpen.

Some sharpeners may suggest to form a straight secondary bevel on the convex scissors, but it should be understood that this will only change the line of blades and the efficiency of this type of scissors will significantly decrease.

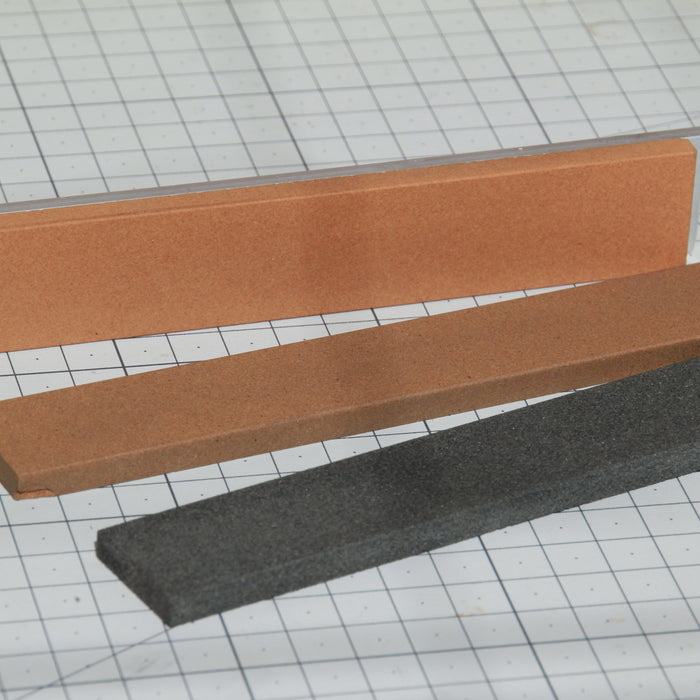

Water stones are also used in the process of sharpening certain types of scissors, at certain stages and are combined with the use of other devices already described.

Here is an example to help you understand. A wet water sharpening stone is used to straighten the support surface of convex blades of barber scissors on a water stone at 2000 - 3000 grit, after machining on a horizontal disk or after sharpening with the special clamp of a household sharpener. This is followed by a final finishing of the radial surface.

A water sharpening stone, no matter how good it is, is not a perfect tool, and professionally honing certain surfaces of particularly curved blades is just not possible. In that case, such planes simply should not be maintained and should be left as is, so as not to make them worse than they are.

3. Main technical requirements

Among the main technical requirements that can be made to the scissors are the following:

- Steel hardness at least 55 - 56 HRC

- The scissor blades must fit tightly together

- The sharpening should provide a cut by any part of the blade

- The hinge joint must be adjusted to provide an easy and smooth coupling movement to avoid the formation of a rim

- Scissors made of carbon steel must have a protective coating

- The sharpening angle should be about 60 to 70 degrees for kitchen, office, crafting, garden, and 80 degrees for metal scissors. Hairdressing scissers are considered separately, depending on the model - from 38 degrees and lower

- When checking the sharpness of the cut, it should be done easily both with the left and right hand

-

Regular maintenance as a method of maintaining the technical properties of the tool

4. Conclusion

In skilful, experienced hands, it is possible to sharpen any scissors professionally on any equipment with the difference in time consumption. How much quality work will cost is a different question.

Let us assume that some very advanced stylists and hairdressers may have about a couple of dozen different expensive scissors of several different subspecies and different sizes. A hairdresser needs his tools to cut hair like his own hands and it is unlikely, given the cost of his tools, that the cost of sharpening will be crucial to him. The quality and speed of sharpening will be the most important factor.

It follows that electric sharpening machines are designed for volume and speed of processing orders, while all others are designed for household sharpening. Manual sharpening is mostly aimed at individual orders.

In other words, if you are in no hurry, you can go to a master sharpener for manual sharpening. If you need a complex sharpening and quick handling, go to a sharpening shop that has experience working on more complex equipment.