Introduction

The sharpening of knives can be called an art that not everyone can master and not every device is able to do the task properly. Even minor errors that can only be viewed under a microscope can lead to unwanted and pricey issues during use.

First and foremost, this applies to the sharpening angle that must be used depending on the type of knife, the quality of the blade material, and its purpose, so it is impossible to give a universal recommendation for the angle. Very often misunderstandings lead to technical difficulties and mistakes. However, it is worth asking a question whether there is an average angle value that can be used for the sharpening any knife or not.

So today we are going to look at the issue of knife sharpening angles. Someone may argue that there is nothing complicated here because there are tables and it is possible to stick to the already-proven values and follow the tips. We do not want to complicate anything, but in this matter, not everything is as unambiguous and simple as it seems at first glance.

1. Definition of the sharpening angle

If we consider the sharpening angle of a knife or any other cutting tool from the theoretical side as a geometrical concept, an angle is a figure consisting of a point and two rays coming from this point. The rays are called the sides of the angle, and the common point is the apex of the angle.

The picture above shows an angle with the apex at point O and sides a and b.

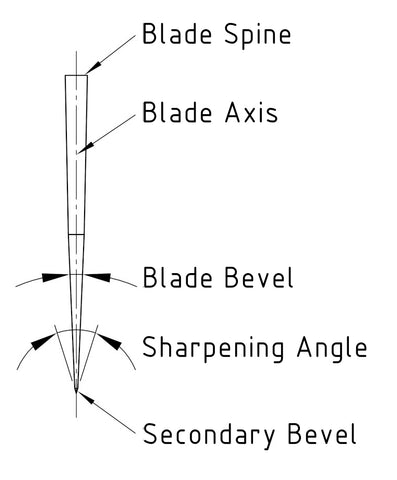

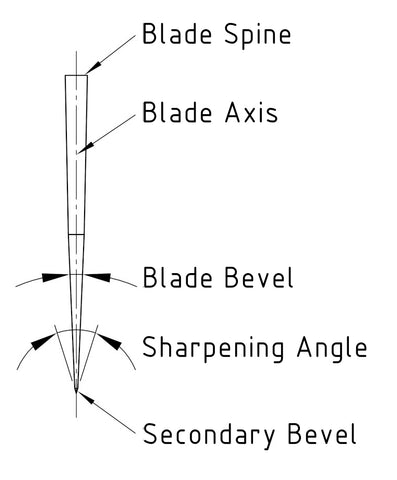

In our context, the sharpening angle is the angular value in degrees that is formed by two sides of the blade, often two and more rarely one secondary bevel. These two planes form a fine convergence and that is how the cutting edge is formed after sharpening.

The config of any knife blade consists of several structural parts, among which the following technological parameters are important with respect to the sharpening angle:

- Height of the bevels, which forms the primary convergence to the cutting edge

- Thickness behind the edge (TBE), which is formed by the convergence of the sides of the blade bevels, and approximately in the middle of which the cutting edge will be formed

- Overall width of the blade - at this point it means that the sharpened part of the blade with the secondary bevels must match (visually) the width of the blade, which limits the choice of the sharpening angle

1 - blade width, 2 - spine, 3 - blade flat, 4 - bevels, 5 - secondary bevels, 6 - TBE

1 - spine, 2 - blade sharpening angle, 3 - bevels, 4 - secondary bevel, 5 - cutting edge

The above-mentioned parameters are connected in many ways, and it is important to take them into account as a whole config of the knife.

Along with these parameters, the purpose of the knife, the material of the blade, and its proper heat treatment, as already mentioned at the beginning, play an important and even primary role.

You should also bear in mind, that such config criterias, as the ergonomics of the handle, along with the steel, geometry, and other aspects contribute to the performance of the knife.

The purpose of this article, however, is probably not to find out which angle to choose, but to give the reason why one angle or another is chosen and to allow the reader to understand the very principle on which such a decision is based. In fact, this is quite a complicated topic and it is possible that a beginner will not understand some of the terms.

2. Practical use

Speaking of sharpening angles, the first thing to say is that there are presumably two fundamental principles. On the one hand, the greater the angle, the higher the edge retention, but the worse the cutting quality. On the contrary, the opposite is also true, that the sharper the angle, the better the cutting quality, but the stability of the cutting edge suffers.

Based on this guess, we can conclude that there may be a relatively optimized angle, which on the one hand will allow having a blade with a sufficient level of stability of the cutting edge and a sufficiently good and effective cutting.

It is necessary to understand what is the angle at which any knife stops function properly. It is also necessary to understand what is the angle at which the knife edge can get serious damage, which, one way or another, will require serious sharpening work.

Let us assume that we have a knife of some steel with certain parameters and we can not decide at first at what angle to sharpen the knife, so how do we proceed?

One thing we know for sure, and even a beginner sharpener can guess it, is that some angle for a knife with a certain steel blade may be suitable and some may not. It is this moment that is the starting point for understanding the gist of it all.

From a large number of sources, you can learn that even the bests knife with a blade of high-quality steel, with good sharpening and high level of sharpness, will lose its sharpness after a certain number of cuts, and this is an indisputable fact.

It is just as correct to assume that one or the other steel at the same sharpening angle will produce a different number of cuts when cutting the same material. The factors that lead to this result are secondary at this point. It should be emphasized here that if we compare the performance of steels, such an analysis would be justified.

And what happens if you need to check the efficiency of the knife cutting instead of comparing the quality of steel with each other? The answer suggests itself - it is necessary to sharpen the blade of the knife at different angles and check the cutting result on the same material, which will reveal the capabilities of the steel or prove the opposite. Quite often a rope made of natural materials is used for such tests because a rope made of synthetic materials is not able to damage the cutting edge in any significant way. Thus, you will get the answer to your question.

In fact, it all comes down to the choice of a larger or smaller angle, and that choice is based on two technological parameters of steel, which are often opposite things - the hardness of steel and its ductility.

It has already been mentioned that the smaller the angle, the sharper the blade, but the more susceptible the cutting edge is to damage. The larger the angle, the less susceptible the cutting edge is to damage, but the quality of the cut is worse.

The lower the hardness of the steel and the smaller the sharpening angle, the more likely the cutting edge will suffer permanent damage. In this case, greater angles are appropriate. This also means that at small sharpening angles, damage may occur on a sufficiently hard steel blade, but the damage will be of a very different nature.

If the angle is chosen properly and the knife is used as intended, the blade with softer or harder steel will not suffer significant damage. Each steel has a recommended level of hardness/ductility balance and if the manufacturing process has been followed, even the most basic steel will serve well and last a long time.

We ponder this, only to discover what really lies at the heart of the question of how to choose an angle.

Such things are unlikely to be done by a large number of users, and that is understandable. The average user needs a guide or rules, like a manual, to use when choosing a sharpening angle.

3. Angles and their purpose

Based on all the above arguments, we can suggest the following groups of angles and materials which you can cut with one knife or the other.

Angles less than 15 degrees

These angle values are used only for cutting very soft materials and are not expected to come into contact with any surface that could mechanically damage the cutting edge. This range of angles can be used for dangerous razors with a very delicate cutting edge and are expected to be used carefully for their intended purpose.

15 – 20 degree angle

The blades of knives or cutting tools with these angles are very sharp. Extreme care and controlled contact with the cutting board are recommended for kitchen knives. They should be used exclusively for their intended purpose. This includes wood knives and cutters, and special kitchen knives.

20 – 30 degree angle

Sharpening angles between 20 degree angle and 30 degree angle compared to general recommendations are still rather small and blades with such angles can have a brittle edge. However, there is a fair amount of knives on the knife market for slicing soft foods, meat, and fish. Especially among such knives, specialized Japanese knives with small sharpening angles and high-hardness steel stand out significantly.

It is also worth mentioning that there is a large number of other knives, the cutting edge of which is sharpened in the same range. These include specialized knives, hunting knives, pocket knives, and some national knives. We recommend careful handling and moderate controlled contact with hard surfaces, whether it is a cutting board or an animal bone.

30 – 40 degree angle

Most knives which are used both in professional activities and in the household, have blades sharpened within a range of 30 to 40 degrees (e.g. benchmade knives have a 30-35 degree inclusive angle). Almost all kitchen knives, pocket folding knives, and tourist knives belong to this group. The cutting edge of such knives will have sufficient edge retention and will have a rather good cut. Contact with hard surfaces is possible with no special concern.

Angles of more than 40 degrees

Knives with such angles will have a fairly good and stable cutting edge, but they will not be efficient.

If the cutting edge of the knife is not very strong and is intended for rough use and work on hard materials is possible, then angles of more than 40 degrees are fine.

General tip. If the knife blade has a fairly small thickness behind the edge and a small cutting edge area, you can sharpen it to a smaller angle if you know how to do it. If it is going to be used for hard materials, you should choose larger angles. The larger angles even with small TBE will give you a reasonably good cutting quality. In other words, there is no point in going below 40 degrees on an EDC knife.

4. Practical test examples

4.1. Test number 1

For the first performance test of the sharpening angles, two knives with reasonably good steel from the middle and high-quality range were chosen. The sharpening angles chosen were 40, 36, and 30 full degrees. These values cover a fairly wide range of the knife market.

The value of 40 degrees, with slight variations, is often used on mass-produced knives.

The 30 full degrees was chosen as the second angle since the vast majority of kitchen chef knives today have a similar value. Let this be a certain point of risk, where the cutting quality is quite good and there is a danger of losing retention. Obviously, it should be understood that the sharpening angles of knives, even in the kitchen segment, can and will vary sufficiently.

The 36 full degrees is the third angle, and it was chosen as the simple arithmetic average value.

Naturally, in order to carry out proper research one would have to check many other angles, but in real life, it is technically difficult to accomplish and will not work in reality. For this reason, we should choose to rely on some realistic data.

The cutting test was performed with the same material and the character of damage of the knives was almost the same, but the cutting quality of the knife with a greater angle with the same number of cuts was worse.

4.2. Test number 2

Another similar test has slightly changed the task description and we can return to the idea expressed above about the optimal angle for a particular knife. To do this, we need to test the cutting efficiency at different angles and work with the same material.

We tested 4 different knives from the medium price segment, and 3 different steels (CTS 204P, Elmax, AUS 8), and the blades were sharpened with 4 abrasives. For the angle of sharpening we chose the value of 24 full degrees. This angle with a slight variation can be found on a large number of different knives now - Japanese and European kitchen, ethnic hunting knives (Scandi), carpentry tools, etc. As a material for the tests, a jute rope with a diameter of 36 mm was chosen.

To pass the test, the rope had to be cut 100 times. After every 20 cuts, the quality of the cutting edge was checked on paper and if the knife coped with the paper, the cutting of the rope was continued. After 100 cuts, the cutting edge was checked with a microscope.

The AUS 8 knife failed with a bang on the first 20 cuts. All other knives passed the test about equally well.

In fact, there could be many reasons for this. We can assume that sand inclusions in the rope material could have damaged the cutting edge. Poor knife sharpening could be the cause. It is also possible to think that the steel was not designed for a certain purpose. Or perhaps the steel was not suitable to retain a certain sharpening angle. As a further reason, the wrong choice of abrasives for a particular steel could have been the cause.

However, all of these hypotheses were incorrect and have been disproved in practice.

From all the results of the AUS 8 steel blade test, one short and precise conclusion was drawn - the heat treatment of the steel was not done properly and the steel turned out to be too ductile.

Thus, if you do not reach the heat treatment level prescribed by the steel manufacturer and reduce the hardening level, it will not increase the strength of the blade, but on the contrary, it can degrade the quality of steel and its physical characteristics.

Summary

Some conclusions can be drawn from all of this, specifically:

- The choice of a particular sharpening angle depends on the primary function of the knife, which means that if the knife is intended to be used for work, smaller angles can be used. If the knife is used on a rare basis, larger angles are fine.

- The best choice of angle can be suggested as a concept of sharpening angle in combination with a micro secondary bevel

- You have to choose the right steel for a knife of each function. It is simply impossible and wrong to use the same steel with different hardness levels for knives of different purposes