Tool Sharpening

Sharpening of Cutting Tools The use of any cutting tool inevitably leads to wear and a reduction in the sharpness of the cutting edge. The cutting edge is the working part of the tool, formed by the convergence of two...

Japanese knives stand out for their strength, sharpness and durability. However, even these cutting tools need to be sharpened from time to time. Knifemakers use sharpening whetstones and specialized devices for this purpose. To keep your Japanese knife blade edge always sharp, you should understand the sharpening process and choose the proper sharpener. Below we will consider the peculiarities of processing such products and the devices used.

Blades of this type can be found in a professional kitchen. These are various narrow-specialized and universal models. They are popular among professionals due to several features:

Also, most Japanese models have a single bevel blade grind. This shape of the cutting edge requires special skills in work. Therefore, to use a Japanese knife for professional purposes one will require a fair amount of experience.

Before beginning you need to understand exactly what steps one must take to restore the sharpness of a knife. There are two ways to make the cutting tool edge sharp:

Due to the high level of hardness of the steel, Japanese knives do not need to be sharpened very often. It is more common to hone the cutting edge of Japanese knives. You do not need to use a sharpening stone or other devices for this purpose. After honing the edge, the knife blade will get sharp.

Please note that honing allows just a temporary restoration of the shape of the cutting edge. Eventually it will lose its sharpness and will require a proper sharpening.

A knifemaker would use a special sharpening stone. A beginner, however, will find it quite difficult to cope with such a task. That is due to the fact that Japanese knives have a shallow sharpening angle.

Sometimes a special water whetstone is used for sharpening. Manufacturers produce such stones in a rectangular shape. A water whetstone can have different grits. Therefore, for high-quality sharpening, you will need several stones. Restoring the sharpness of a Japanese knife on a water stone is done in several steps:

Using stones of different grits helps to repair serious damage and make the blade sharp. However, holding the knife at the required angle is not easy and requires a certain amount of experience. Thus, this method will be difficult for a beginner.

You should wash the blade under running water to remove any steel particles from the surface left after sharpening.

ATTENTION: Do not wash your kitchen knives in a dishwasher. Chemicals and high temperatures can affect the steel quality of the cutting tool and reduce sharpness.

There is a wide range of models on the market that are powered by an electric engine and a rotating abrasive wheel. From the point of view of some users, it may seem that such a sharpener is the best option for knife sharpening. But one should be aware of several electric knife sharpeners' features:

Given these features, it is better not to use an electric sharpener to try to make a Japanese kitchen knife sharp. Doing so may result in blade damage.

Products of this type are extremely widespread. They are used for knifemaking, cutting edge restoration, as well as for sharpening when a cutting tool looses its sharpness. The main advantages of manual sharpening with the help of a special tool:

When using a mechanical sharpener, a person controls the pressure force of the abrasive stone on the knife. And the absence of an electric drive means that there will be no accidental blade damage.

The use of a grinder can cause serious blade damage due to the high rotation speed of the belt, the pressure and strong friction, which heats the blade. This has a negative effect on the hardness of the blade. Therefore, it is better not to use a grinder to work with Japanese knives.

If this is the only possible option, you should only work at a very low speed. This sharpening method involves manual setting of the sharpening angle. The knife gets gradually pressed to the abrasive surface. At the same time you should always monitor the progress. Due to the rotation of the abrasive element, there is a high risk of damaging the blade.

To avoid overheating of the blade, there should be water cooling of the stone. Besides, you should constantly monitor the temperature of the metal. If the temperature goes up, the blade should be cooled down.

Besides, it is not a good idea to use a grinder sanders in a kitchen, it is more suitable for a workshop.

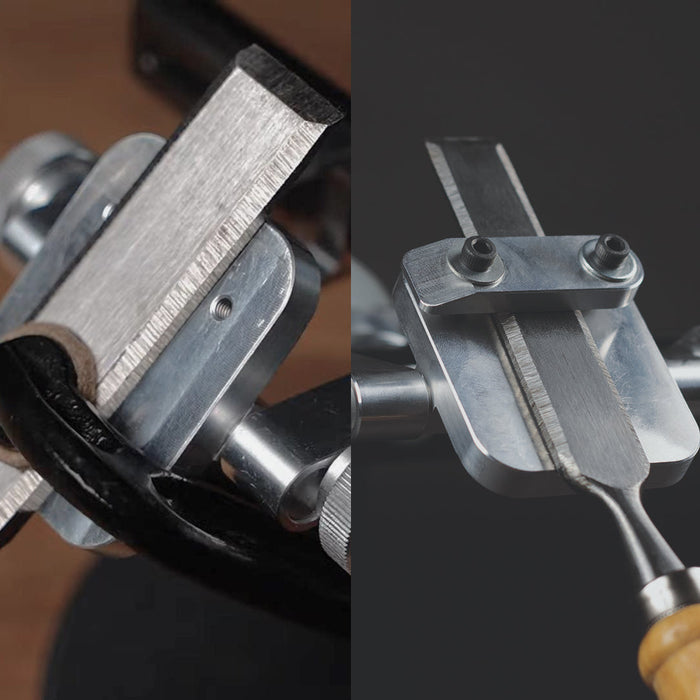

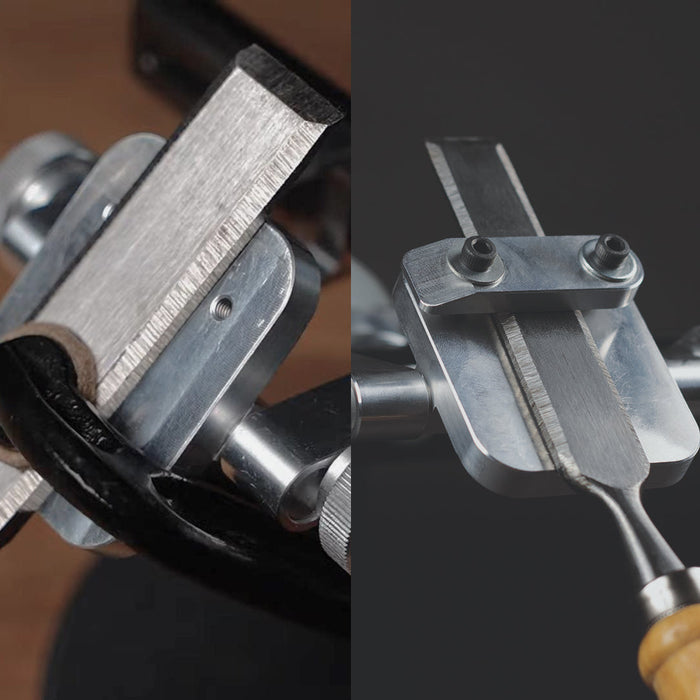

The TSPROF sharpening systems are popular among knife makers, sharpening professionals, beginners, knife lovers and collectors. The TSPROF models are very common due to their simple design. Any person without special skills can cope with the work. In addition, the demand for these sharpening systems is due to a number of advantages:

Other advantages include the surface stability of the sharpeners. Their heavy bases allow them to be placed securely on a table, workbench or other surface.

A Japanese knife can be sharpened on one or both sides. The method of restoring the cutting edge is determined according to the features of a particular cutting tool. The sharpening process is quite simple:

After you complete these steps, you can mount an abrasive with a finer grit. This helps to remove scratches and irregularities on the cutting edge. Repeat the same steps with finer abrasive stones until you get the desired condition of the cutting edge.

Professional kitchen chefs favor Japanese knives for their sharpness and durability. To keep your blade in the best condition, you should sharpen it manually. The best option is to use a manual sharpener. This device works equally well for beginners and professionals and allows you to make a sharp cutting edge in the shortest possible time.

When choosing a sharpener, one should pay attention to its specifications, as well as the sizes of knives that can be sharpened with this or that sharpener. With this approach, you will be able to choose a device that meets your purposes.

Sharpening of Cutting Tools The use of any cutting tool inevitably leads to wear and a reduction in the sharpness of the cutting edge. The cutting edge is the working part of the tool, formed by the convergence of two...

Slip stones are special sharpening stones designed for sharpening special cutting tools, such as woodworking equipment. They come in various shapes and sizes. Learn more about their types and purposes in this article.

A file or a special abrasive? In the world of sharpening, the word "file" might sound a bit out of place, especially for those not too familiar with hand tools. Most people would associate it with a rough metalworking tool,...

{"one"=>"Select 2 or 3 items to compare", "other"=>"{{ count }} of 3 items selected"}